Lifting and Tipping Devices

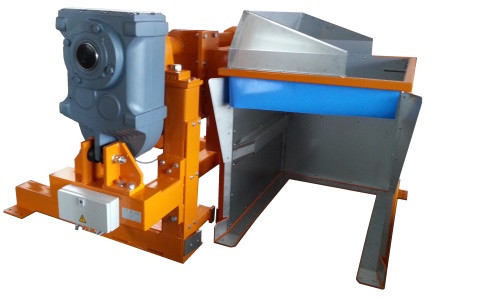

Tipper T-200 SL

Brief Description

- task of the tipper is the emptying of bins filled with bulk material (e.g. cut filler tobacco)

- infeed of bins manually or automatically

- side-load infeed of bins (from left or right side possible)

- swivel drive optionally on left or right side possible

- specific adapter depending to the bin (e.g. for C48 / C90 cardboard boxes, plastic bins etc.)

- special designs on request possible

| Technical Data (Basic Design) | T-200 SL |

|---|---|

| permissible payload: | 200 kg |

| maximum dimensions of the bin (length × width × height): | 1,200 mm x 800 mm x 930 mm |

| minimum infeed height: | 52 mm |

| time per tipping process: | approx. 90 s |

| angle of tipping out: | approx. 160° |

| max. height of slewing: | approx. 2,870 mm |

| total width: | approx. 2,320 mm |

| total length: | approx. 2,420 mm |

| weight: | approx. 1,100 kg |

| electrical service: | 400 VAC, 50 Hz, approx. 1.2 kVA |

Tipper T-250

Brief Description

- task of the tipper is the emptying of bins filled with bulk material (e.g. cut filler tobacco)

- infeed of bins manually or automatically

- infeed of bins in tipping direction

- swivel drive optionally on left or right side possible

- specific adapter depending to the bin (e.g. for C48 / C90 cardboard boxes, plastic bins etc.)

- optionally pneumatic operated retaining flaps

- special designs on request possible

| Technical Data (Basic Design) | T-250 |

|---|---|

| permissible payload: | 250 kg |

| maximum dimensions of the bin (length × width × height): | 1,200 mm x 1,000 mm x 1,000 mm |

| minimum infeed height: | 40 mm |

| time per tipping process: | approx. 90 s |

| angle of tipping out: | approx. 165° |

| max. height of slewing: | approx. 2,990 mm |

| total width: | approx. 2,025 mm |

| total length: | approx. 2,650 mm |

| weight: | approx. 1,200 kg |

| electrical service: | 400 VAC, 50 Hz, approx. 1.7 kVA |

Tipper T-500

Brief Description

- task of the tipper is the emptying of bins filled with bulk material (e.g. cut filler tobacco)

- dust minimized design

- infeed of bins manually or automatically

- infeed of bins in tipping direction

- swivel drive optionally on left or right side possible

- intake frame adapted to the bin

- integrated bin sealing frame (adapted to the bin)

- pneumatically actuated retaining flaps

- pneumatically actuated lifting device

- pneumatically actuated bin centring device

- optionally adapter (e.g. for C48 / C90 cardboard boxes, standing on Euro-pallet, plastic bins etc.)

- special designs on request possible

| Technical Data (Basic Design) | T-500 |

|---|---|

| permissible payload: | 500 kg |

| maximum dimensions of the bin (length × width × height): | 1,315 mm x 1,315 mm x 1,700 mm |

| minimum infeed height: | 220 mm |

| time per tipping process: | approx. 90 s |

| angle of tipping out: | approx. 160° |

| max. height of slewing: | approx. 3,500 mm |

| total width: | approx. 2,800 mm |

| total length: | approx. 2,850 mm |

| weight: | approx. 2,500 kg |

| electrical service: | 400 VAC, 50 Hz, approx. 2.5 kVA |

| compressed air: | 6 bar (approx. 60 l / cycle) |